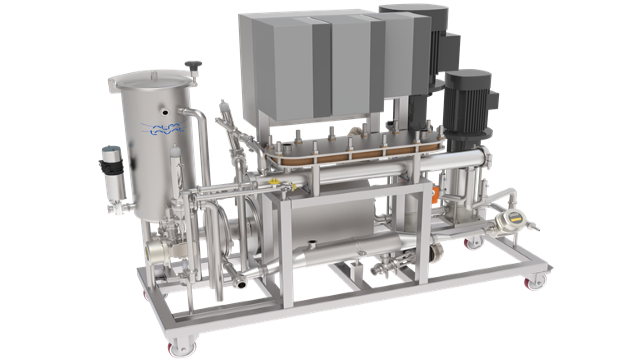

Lab/pilot units

Alfa Laval offers a wide range of small-scale units and pilot plants which are ideal for on-site testing. Valuable data is gained for evaluation of process feasibility, determination of design and up-scaling, optimization of existing production lines or processing of high-value products

Small-scale units and pilot plants

In order to ensure the optimum solution, it is often advisable to conduct experiments on a small scale. These can be used to establish process feasibility, determine design data for up-scaling, optimize existing production lines or even carry out small-scale processing of high-value and/or low-volume products.

Our range of small-scale units and pilot plants is based on the unique plate-and-frame modules or the full-fit sanitary spiral elements, or a combination of both. The sizes vary from only a few litres of test media volume in the Alfa Laval LabUnits up to 1,000 litres in the Alfa Laval PilotUnits. it is possible to test all filtration processes: Reverse osmosis, nanofitration, ultrafiltration and microfiltration.

On-site testing or at Alfa Laval pilot facilities

Alfa Laval provides small-scale modules, units and pilot plants for testing on-site in connection with other process equipment and for testing at our own state-of-the-art Membrane and Application Development Test Centre in Nakskov, Denmark. In both cases, we also provide highly skilled process consultancy services.

Benefits

- You can make the first screening evaluations in your own laboratory and thus get the correct answers to vital questions

- The same design is used for both small-scale and industrial scale equipment which allows you to develop new processes and products

- The data gathered is accurate and reliable for easy up-scaling

- Alfa Laval has its own membrane and application development test centre where experts are ready to help you with process know-how and test work

- You can conduct experiments with both plate-and-frame and spiral wound module configurations - and all filtration processes

How it works

Physical separation

Membrane filtration is a physical separation process in which the driving force is the difference in pressure between the two sides of a special membrane. This process is characterized by the ability to separate molecules of different sizes and characteristics.

Almost all industrial membrane filtration is carried out as cross-flow filtration, where the liquid being filtered flows parallel to the membrane at high velocity and under pressure.

Physical barrier

In its most basic terms, membrane filtration involves passing a single feed stream through a membrane system that separates it into two individual streams, known as the permeate and the retentate. The membrane that separates them is a physical barrier with highly specialized characteristics - a barrier that only certain selected components in the feed stream can pass through.

Passing through

The pores of such membrane material are so small that they are measured in Angstrom (10-10 m), and pressure is required to force the liquid through them. In fact, the pores in the membranes used for nanofiltration and reverse osmosis are so small that they cannot be seen even with a scanning electron microscope.

Long experience with membranes

Alfa Laval's experience within membrane filtration dates back almost as far as the technology itself, and we wish to share our experience with you.