PX

The PX range of industrial centrifuges is specially developed for processing of nearly all types of vegetable oils, lard, tallow and fish oil. These centrifugal separators provide superior separation quality, gentle and efficient product treatment and secure high yield. They are widely used in continuous degumming, neutralization, dewaxing, and washing in vegetable oil and animal fat refining industries. Premium quality centrifugal separators for small, medium and large plant capacities.

High separation capacity and maximized efficiency

- Centrizoom technology for optimal handling of high viscosity media

- Bowl is made of high performance stainless steel for optimal resistance to metal fatigue and superior erosion protection

- Low energy consumption thanks to bottom feed hermetic design

- Robust and easy to maintain

- The widest range on the market with refining capacities from 50 to 1500 tons per day

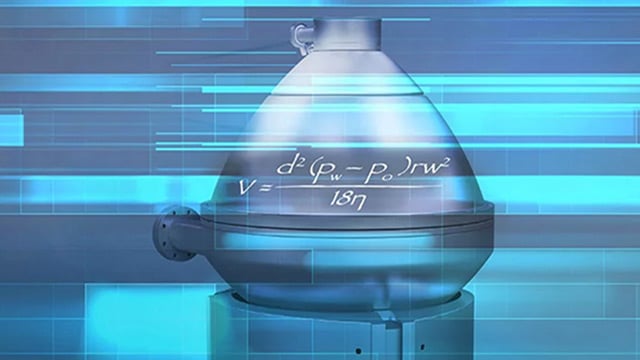

The PX range is based on a unique, semi-hermetic design concept. The hermetic, bottom-fed inlet ensures a gentle, non-destructive acceleration of the feedstock up to full bowl speed. The flow area for the feedstock has been increased to minimize inlet pressure drop. The outlets on the heavy and light phases are open, reducing the pressure drop across the separator. The feed-pressure requirement of the machine is therefore low.

The outlets are equipped with stationary paring devices for removal of the different phases. The paring disc on the light phase is fixed, while the paring tubes on the heavy phase are adjustable.

By adjusting a positioner on the heavy phase outlet, the operator can reduce or enlarge the paring diameter of the paring tubes. This patented innovation makes it possible to adjust the position of the separation interface during operation, facilitating optimal separation.

With the working environment in mind, the PX range is designed to operate at low noise levels. This is achieved by means of a rubber-damped bearing assembly, jacketed frame and an outer bowl design engineered for low wind noise.

PX range - most demanded separators in our portfolio for fats and edible oil processing

PX 115

- Easy to operate and maintain

- Robust and reliable

- Gear drive

- Automatically adjustable interface

- Flexible installation options

- Up to 1500 tons per day

PX 115e

- Easy to operate and maintain

- Robust and reliable

- Direct drive

- Automatically adjustable interface

- Flexible installation options

- Up to 1500 tons per day

How it works

The oil to be separated is fed into the separator bowl from the bottom through a hollow spindle, and enters the disc stack. The heavy phase and heavy sludge are forced towards the periphery of the bowl, while the light phase flows towards the centre of the bowl, from where it is pumped out for further processing. The heavy phase is led over a top disc into a chamber where an adjustable paring device pumps it out of the separator. Sludge collects in the sludge space and is discharged intermittently and automatically. The discharge is achieved by a hydraulic system, which at preset suitable intervals forces the sliding bowl bottom to drop down, thus opening the sludge ports at the bowl periphery. The sludge is collected in the frame, and leaves the centrifuge via a cyclone.

The Separator Innovator

Would you like to know more about our innovations in separation technology? Click on the link below. Alfa Laval invented the first disc stack separator and has led the way in the development of centrifuge technology for over a century. We are glad to share with you the expertise we have gained along the way. Visit our Separator Innovator knowledge base to learn more about advancements in separation and the steps Alfa Laval is taking to continue revolutionizing the technology.