Brew series

Alfa Laval disc stack centrifuges have a long history of enabling breweries around the world to achieve higher yields, meet shifts in demand and maintain profitability. Used in pre-clarification, green beer separation, hot wort separation and beer recovery, they ensure minimal levels of oxygen pick up during passage through the separator and the highest standards of hygiene.

High beer separation efficiency combined with energy efficient operation

- Centrifugation provides breweries with swift beer clarification with no loss of aroma or CO2

- Increased clarification capacity: reduced fouling of filters with preclarification

- High efficiency beer separation enables quicker turnover of fermentation tanks

- Reduced product losses: beer centrifugation results in more concentrated solids compared to gravity settling

- Patented beer brewing equipment and hermetic design leads to low to zero oxygen pick up

Alfa Laval is one the major global supplies of high-quality separation equipment to the brewing industry. Our centrifuges have proved crucial in enabling breweries around the world to achieve higher yields and greater efficiency, as well as in helping them meet changing demand patterns from consumers while maintaining profitability. Beer brewery centrifuges from Alfa Laval ensure minimal levels of oxygen pick-up during passage through the separator, which is a major quality requirement for brewers. Hygiene is also a prime focus in all aspects of the design of our brewery centrifuges.

The Brew series beer centrifuges are all used within the following application steps in the brewing process:

- pre-clarification

- green beer separation

- hot wort separation

- beer recovery

With features and options such as our fully hermetic seal that ensures minimal oxygen pick-up in the clarified liquid, SmartEject self-triggering system, which provides intermittent discharge of solids that have a high dry matter content, a specially designed variable frequency drive (VFD) system provides benefits that include low starting current and a short time power supply, and much more, the brewer can customize the separator performance and capacity to a given application task to the optimum yield.

Brew range

Alfa Laval beer centrifuges have proved crucial in enabling breweries around the world to achieve higher yields and greater efficiency. They ensure minimal levels of oxygen pick-up during passage through the separator, which is a major quality requirement for brewers. Hygiene is also a prime focus of the design of our brewery centrifuges.

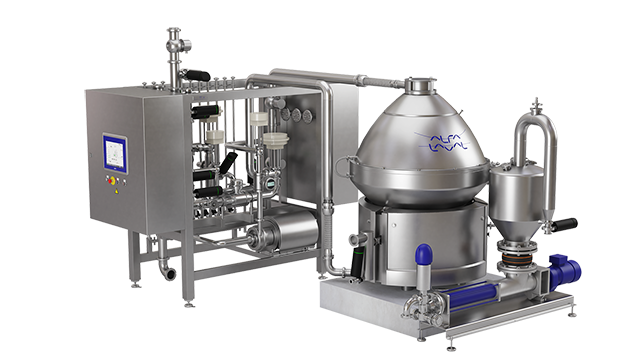

Brew 20

Multi-purpose centrifuge for craft brewers and microbreweries

- Up to 15 hl/h

- Low oxygen pick-up – axial hermetic outlet

- Simple to operate

- Plug & Play skid

- Low maintenance costs

Brew 80

Multi-purpose centrifuge for craft brewers

- Up to 50 hl/h

- Low oxygen pick-up – axial hermetic outlet

- Turbidity triggering of solids discharge (included in upgraded Plus version)

- Capacity control by inlet turbidity (included in upgraded Plus version)

Brew 80

Multi-purpose centrifuge for craft brewers

- Up to 50 hl/h

- Low oxygen pick-up – axial hermetic outlet

- Turbidity triggering of solids discharge (included in upgraded Plus version)

- Capacity control by inlet turbidity (included in upgraded Plus version)

Brew 301

Multi-purpose centrifuge for small breweries

- Up to 200 hl/h

- Low oxygen pick-up – OxyStop seal

- Basic and easy to operate

- Skid-mounted separator and system

- Turbidity triggering of solids discharge

- Siemens Automation

Brew 250

Polisher for small breweries and сraft brewers

- Up to 180 hl/h

- Hermetic Design™ means practically zero risk of oxygen pick-up

- Low power consumption

- Basic and easy to operate

- Skid-mounted separator and system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity (included in upgraded Plus version)

- Siemens or Allen Bradley Automation (included in upgraded Plus version)

Learn more about Brew 250 Plus

Brew 250 Plus

Polisher for small breweries and craft brewers

- Up to 180 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Basic and easy to operate

- Skid-mounted separator and system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 350

Polisher for medium size breweries and craft brewers

- Up to 300 hl/h

- Hermetic Design™ for close to zero oxygen pick-up

- Low power consumption

- Complete system with full flexibility

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 350 Skid

Polisher for medium size breweries and craft brewers

- Up to 300 hl/h

- Hermetic Design™ for close to zero oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 501 H

Multi purpose for larger size breweries and craft brewers

- Up to 500 hl/h

- Center to Center

- Zero oxygen pick-up and low power consumption

- Complete system with full flexibility

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 600

Multi-purpose for larger size breweries and craft brewers

- Up to 650 hl/h

- Hermetic Design™ means practically zero risk of oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 600e

Multi-purpose for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic Design™ means practically zero risk of oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 701

Polisher for larger size breweries and craft brewers

- Up to 650 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Low power consumption

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley Automation

Brew 701e

Polisher for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Very low power consumption with eDrive (direct drive)

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley automation

Brew 701 eMotion™

Polisher for larger size breweries and craft brewers

- Up to 750 hl/h

- Hermetic design means practically zero risk of oxygen pick-up

- Extremely low power consumption with eDrive (direct drive) and eMotion (reduced air friction)

- Separator with complete associated system

- Turbidity triggering of solids discharge

- Capacity control by inlet turbidity

- Siemens or Allen Bradley automation

How it works

The heavier solids phase is collected at the periphery of the bowl, where it is discharged intermittently via the centrifuge cyclone. The solids are discharged by a hydraulic system below the separation space in the bowl, which forces the sliding bowl bottom to drop down at suitable intervals, thus opening the solids ports at the periphery of the bowl.

Craft brewing

Share your passion for craft brewing