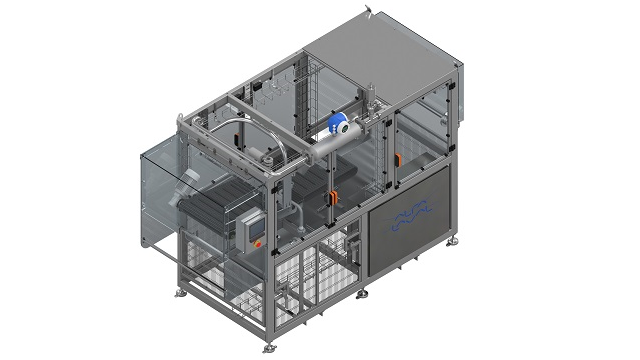

Astepo grande filler

Fully optioned non-aseptic filling system for flexible bags fitted with standard 1-inch spouts for food and beverages.

Ideal for food and beverages

Alfa Laval Astepo Grande non-aseptic bag-in-box filling systems are in widespread use all over the world for filling bags with liquids such as wine, water and other shelf-stable products, dense sauces such as mayonnaise and tomato ketchup, post-mix products, syrups and vegetable oils.

There are also special versions available for production set-ups with particular hygiene standard requirements, and particular flexibility needs.

Quick-swap versatility

These filling systems are designed for easy operation and minimal maintenance, and to make it easy to quickly swap between different bag sizes. They can operate with a wide range of different bag and spout types, including dispenser taps for wines or syrups.

Easy integration with carton box system

Grande bag-in-box filling systems can also be linked up to automatic Alfa Laval Astepo Combibox cartoning lines (featuring sealing with either hot-melt glue or adhesive tape). An effectively integrated bag-in-box filling and cartoning process line takes up less space and gives you maximum versatility.

Benefits

- Tried-and-tested filling solution that you know you can rely on

- High-spec standard configurations that boost reliability, filling speed and hygiene

- Wide range of optional capabilities for maximum versatility

- Automated, user-friendly operation – only minimal supervision required

- High hygiene standards

How it works

Accurate filling

The Grande filler system uncaps, fills and caps bags of 2–20 litres in capacity, with a filling accuracy of +/- 0.5%. Input capacities are as much as 14,000 litres per hour, but the filling speed depends on the bag size chosen.

The system uses web bags with front-mounted caps. The bags are separated by a soft horizontal knife designed to protect the film from micro-perforation. A pneumatic system automatically feeds these bags to the filling head.

The cap removal clamps are designed for rapid change-over, and are synchronized with the filling valve by a pneumatic cylinder that ensures easy adjustment and less wasted time. A mass flow meter can be fitted to ensure extremely accurate filling.

Special configurations are available with pre-filling vacuum or a post-filling nitrogen puff, or with a HEPA filter over the filling area.

Versatility is standard

Grande fillers are available as stand-alone units or as part of complete, smoothly integrated Alfa Laval Astepo process lines consisting of a bag-in-box filler, web bag feeder system and a cartoning system, along with an automated cleaning-in-place system (using overheated water or steam, etc.) that cleans all the surfaces in contact with the liquid product. A remote control CIP set-up means no human intervention is needed.

A comprehensive selection of optional equipment is also available to provide additional capabilities.