Carboblend

Alfa Laval Carboblend is a well proven blending and carbonation system for the beverage industries. The carbonation system (> 200 successful installations worldwide) provides continuous, accurate blending and carbonation of beer, soft drinks and other beverages.

A beer carbonation machine developed in co-operation with the brewing industry

- Outstanding blending/carbonation accuracy

- Efficiently dissolves CO2

- Space-savingly compact while versatile and adaptable to different process requirements

- Automatic process control requires less manpower

- Stable and reliable operation and low maintenance requirements for long uptime

Blending - How to use the carbonation system for blending

Carbonation – How to use the beer carbonation system

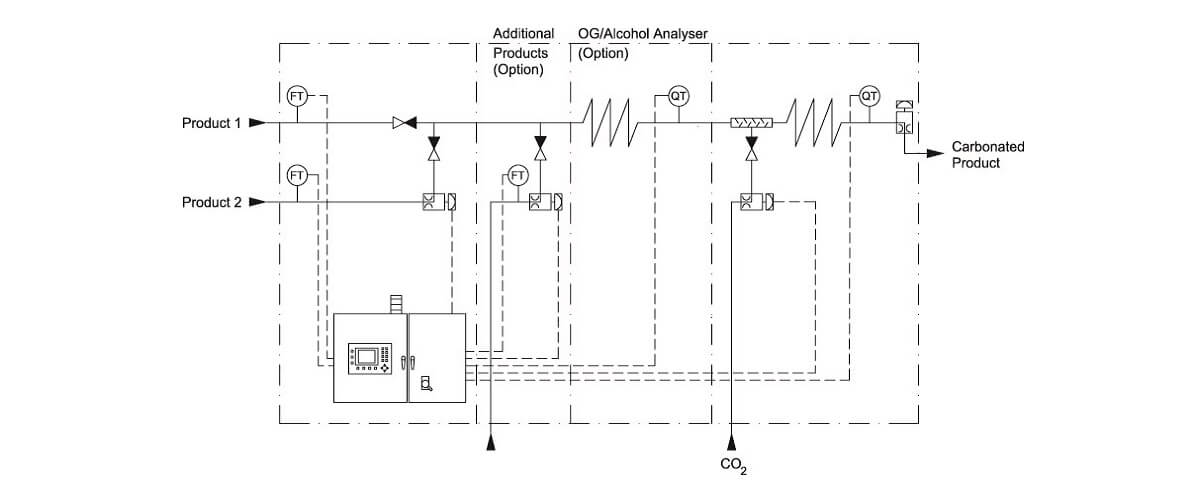

CO2 is injected into the product line directly without utilising any porous disc or sinter candle. A specially designed mixer/accelerator ensures that the CO2 dissolves rapidly in the product through this combination of turbulent flow and increased pressure. An analyzer after the mixer checks the carbonated product for CO2 content. A control valve regulates the CO2 flow to maintain a constant CO2 content in the product. A PLC controls the plant operation. A fail-safe system continually monitors the operation.

Brochure

You can read more about the efficiency, benefits, practicality and technical details of the Carboblend beer carbonation machine by downloading the brochure.