Compabloc Free Flow

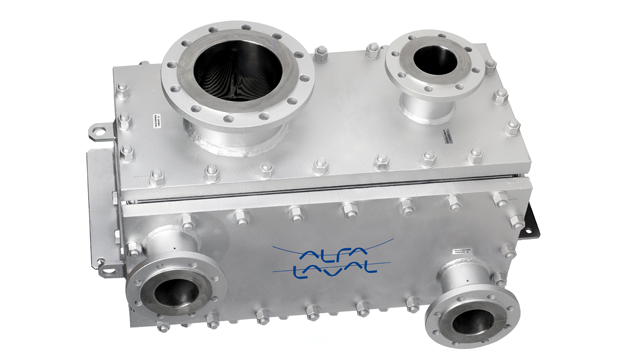

Alfa Laval Compabloc Free Flow is a compact condenser with very high heat transfer efficiency specifically designed for the pharmaceutical industry and the high hygienic requirements of modern API production. The hygienic design, high performance, low operating costs and easy installation combine to ensure patient safety, reliable uptime and production efficiency.

Pack more condensing capacity into existing space in your API production

- Easy to validate – fully meets the requirements for installation in cGMP processes

- All-welded design and available in corrosion-resistant materials, making it the perfect replacement for graphite block or shell-and-tube

- State-of-the-art hygienic design makes cleaning quick, easy and reliable while low hold-up volumes reduce cleaning solvent usage

- Compact size and low weight enable you to increase capacity even when space is limited – perfect for retrofitting

- Proven low operating and maintenance costs

Patient safety and cGMP

Compabloc Free Flow offers state-of-the-art hygienic design and fully meets the requirements for installation in stringent cGMP processes. This makes Compabloc Free Flow suitable for pharmaceutical processes such as API manufacturing

New possibilities with compact condenser

Patrik Arvidsson, Business Manager at Alfa Laval, explains the benefits of using compact condensers in API production.

Ease of cleaning and inspection

Efficient cleaning of the reactor condenser is vital for patient safety. A difficult to clean condenser increase carry-over and cross-contamination between batches. For a multi-purpose reactor this can be disastrous if different medicines mix. It can also be a serious problem for a single-purpose reactor since it reduces traceability. Cleaning and validating the cleaning for a Compabloc Free Flow is quick and easy thanks to the full drainability and absence of crevices, dead spots and contact points on the product side. Inspections are performed easily through the nozzles or by simply opening the panels, giving you full access to all product-wetted surfaces.

Perfect for API manufacturing processes

Graphite blocks are widely used as condensers in API manufacturing processes thanks to their ability to withstand aggressive media. However, as many pharmaceutical companies have experienced, graphite blocks have a major disadvantage. They release carbon particles and resin into the product stream. Compabloc Free Flow is available in corrosion-resistant materials, making it the perfect replacement for graphite block condensers in API manufacturing.

How it works

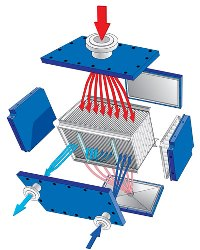

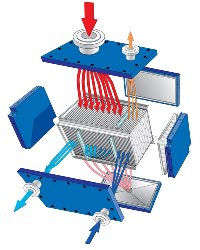

The Compabloc Free Flow comes in two versions. At its core is a stack of corrugated heat transfer plates made of stainless steel or alloy C22 that are alternately welded to form channels. The vapour and the cooling medium flow through alternate channels, causing the vapour to condense on the cold plates. The wide free-flow channel results in a very low pressure drop, making it ideal for deep vacuum condensing duties. On the coolant side, baffles direct the cooling media back and forth through the channels to increase turbulence and thermal efficiency.

The complete plate pack slides inside a steel frame bolted to pressure-retaining heads. Four removable panels contain the inlet and outlet connections and give easy access to all product-wetted surfaces.

Single-pass condenser

This version is suitable when the vapour contains small amounts of inert gases. Vapour enters through the big inlet on the top panel and condenses on the plates. The condensate exits through the sloped, drainable bottom panel.

Two-pass condenser

The two pass version can be used when the vapour contains a larger portion of inert gases. Main condensation takes place in the first pass where the condensable part of the vapour condenses on the plates before exiting through the sloped, drainable bottom panel.

The non-condensable vapours go through the second pass where they are sub-cooled to maximize condensation. Turbulence in the second pass helps to eliminate mist, and vacuum is easily drawn from the outlet of the second pass. With a two-pass condenser there is no need for an additional vapour separator, since separation takes place in the unit.

Customer references

Learn more about pharmaceutical plants across the world using Alfa Laval Compabloc and Compabloc Free Flow as condensers.

Bayer HealthCare Pharmaceuticals

Bayer HealthCare Pharmaceuticals in Berlin (former Schering Plough) have 25 Compabloc condensers made of Hastelloy and titanium installed in processes with high cGMP demands. The units are cleaned with various solvents using a cleaning-in-place (CIP) system. Benefits: space savings, low capital cost & easy installation.

API manufacturer in Switzerland

Installed at for an API manufacturer in Switzerland, the Compabloc Free Flow unit is used a reactor condenser. Its hygienic design is space saving, provides ease of installation and ease of cleaning validation.

Merck

Merck, Germany, installed more than 100 Compabloc condensers made of Hastelloy C22 and 316L after successful tests in a pilot plant. The units are used as reactor condensers and condensers for dryers. Benefits: improved process operation, complies with high cGMP demands & compact.

Shanghai Syntheall

Shanghai Syntheall, China, uses Compabloc condensers made of Hastelloy C22 and 316L as reactor condensers. Benefits: space savings, low capital cost, easy installation.

Download product brochure

Find out why you should make the Alfa Laval Compabloc Free Flow your first-choice condenser in pharmaceutical processes.

You might also be interested in...

Pharma-line

A high-quality shell-and-tube heat exchanger especially developed to meet the high hygienic demands of the pharmaceutical industry.

Pharma X

A compact tube-in-tube heat exchanger module developed for point of use cooling in pharmaceutical water systems. Alfa Laval Pharma-X is designed to remain sanitized even when not in use (standby mode).

Tank cleaning equipment

Using the right tank cleaning device can significantly reduce downtime, while using fewer resources such as water, cleaning agents and energy. Our devices are also designed to increase plant safety by eliminating confined space entry for manual tank cleaning.