Aalborg XW-TG

The Aalborg XW-TG is a water tube, forced circulation exhaust gas economizer designed to utilize thermal energy in diesel engine exhaust gas.

The standard Aalborg XW design has been enhanced to more efficiently utilize the wasted energy after large diesel engines with saved fuel consumption and reduced CO2 emissions as a result.

The Aalborg XW-TG is a water tube, forced circulation exhaust gas economizer designed to utilize thermal energy in diesel engine exhaust gas. The standard Aalborg XW design has been enhanced to more efficiently utilize the wasted energy after large diesel engines with saved fuel consumption and reduced CO2 emissions as a result.

Aalborg XW-TG generates superheated steam for power generation by means of a steam turbine driven generator (turbo generator).

The Aalborg XW-TG is based on and has the same characteristics as our well-known Aalborg XW which is a water tube, forced circulation exhaust gas economizer with double gilled tubes specially designed for heat recovery from diesel engine exhaust gas.

When applied for large heat recovery rates, the heating surfaces are required to be much increased in size and it is increasingly more important to focus on operation reliability to provide full benefit of the relatively high investment.

Features and benefits

- Forced circulation exhaust gas boiler/economizer

- Water tube boiler with gilled tubes for exhaust gas heat recovery

- Robust, well-proven construction, able to withstand vibrations and exhaust gas pulsation

- Heating surface composition which ensures the required output from the most compact unit

- Efficient, well-proven cleaning system with steam or air soot blowers

- Super heater and preheater as an option

Design data

- Steam capacity: 15 - 34.0 t/h

- Heat capacity: 0.1 - 21 MW

- Steam pressure: 18 - 24 bar(g)

How it works

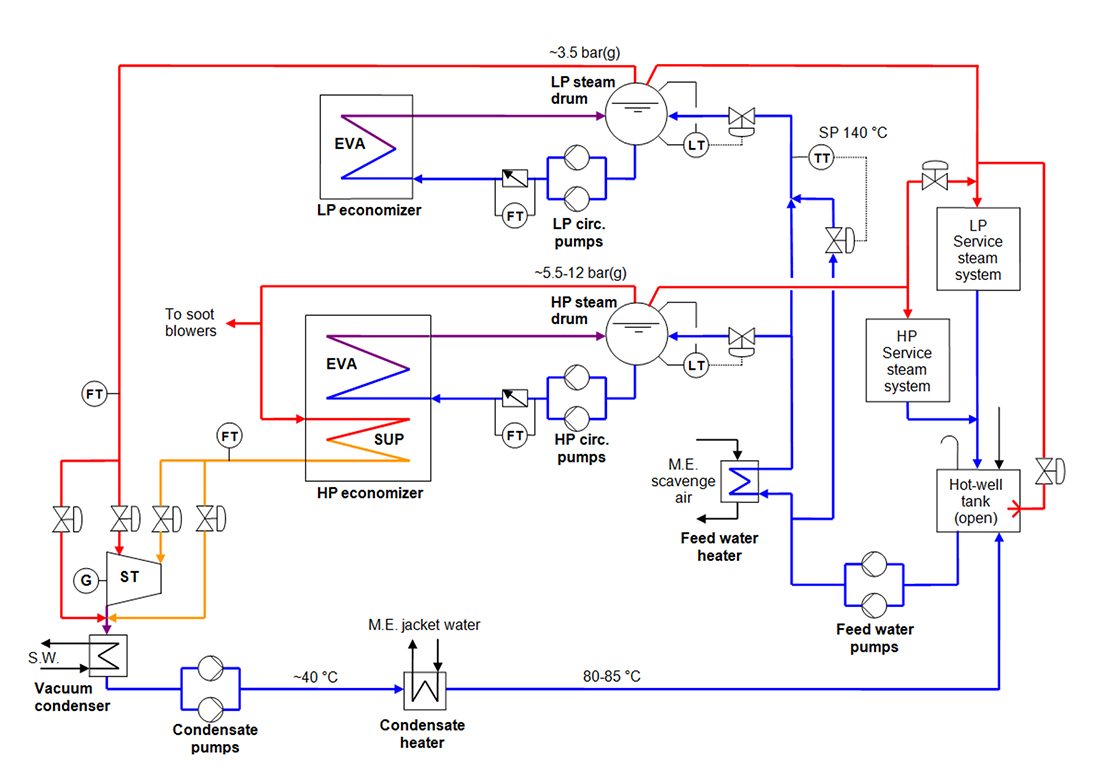

The Aalborg XW-TG can be arranged in many different configurations, e.g. for a single pressure or dual pressure system, according to each individual requirement for steam and power output.

Like the standard version, Aalborg XW-TG is constructed with double-gilled water tubes and operates with forced circulation. However, the Aalborg XW-TG provides superheated steam for power generation by means of a steam-turbine-driven (turbo) generator. Because the heat recovery rates involved demand larger heating surfaces, it also features safety enhancements such as bypass dampers and extended monitoring equipment.

The economizer can be supplied with a dividing wall system for connection of several exhaust gas sources to one boiler. A design with single gilled tubes is also available. The Aalborg XW-TG may be used in conjunction with an oil-fired auxiliary boiler or a separate steam drum, in both cases acting as a steam/water separator.

For enhancement of an efficient, safe and reliable operation, the Aalborg XW-TG is therefore among other things supplied with the following equipment (advantageous for ordinary economizers as well):

-

Steam drum(s) for efficient separation of dry steam forsuperheating

-

High-efficient, electrical operated sootblowers using steamor compressed air as blowing medium for on-load cleaning

-

Fixed nozzle pipes for off-load water washing

-

Extended monitoring equipment (e.g. exhaust gas pressuredrop/temperatures and fire detection)

-

Dampers for by-passing of exhaust gas at low load operation(and in case of emergency)

-

Circulation pumps of canned motor type (with externalcooling) with flow monitoring system

-

PLC based control system including online performancemonitoring and help functions

The Aalborg XW-TG can be arranged in many different configurations, e.g. for a single pressure or dual pressure system, according to each individual requirement for steam and power output.