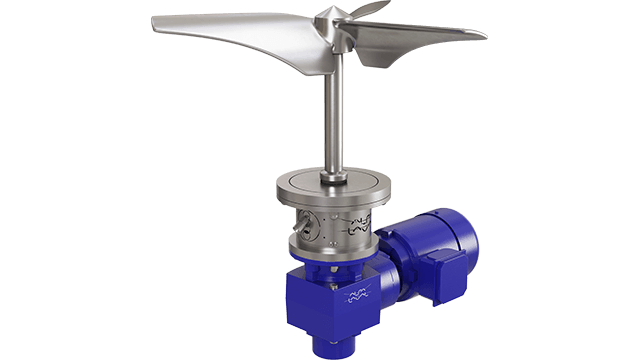

LeviMag UltraPure

The Alfa Laval LeviMag® UltraPure is an aseptic magnetic mixer that uses a patented levitating impeller and advanced design to mix down to the last drop and maximize product yield. Compact, energy-efficient and easy to maintain, it is perfect for biotech, pharmaceutical and demanding hygienic and sterile applications such as those involving serums, vaccines, plasma fractions, bacteria and cell cultures, and APIs.

Superior hygiene, optimized operation

- Optimized flow for higher efficiency and more gentle product treatment

- Mixing down to the last drop for maximum yield due to low agitation and dry-running capability

- Optimized Cleaning-in-Place thanks to full drainability

- Minimized downtime due to ease of maintenance

- Comprehensive documentation for full traceability of the entire supply chain

LeviMag® UltraPure Technology

The levitated design of the Alfa Laval LeviMag UltraPure prevents grinding between the axial parts of the bearings. This significantly minimizes the risk of damaging the media. This is important for pharmaceutical liquids that contain sensitive crystal carriers, for instance.

Service

Get more uptime thanks to low-wear bearings that are easy to maintain and easy for operators to replace on site. No glue or shrink-fit is required. This minimizes downtime. Plus, there is no need for spare impellers. Tools for easy maintenance are also available.

Product models

The Alfa Laval LeviMag UltraPure magnetic mixer is available in five sizes from 100-300 mm. This provides greater process flexibility to handle a wide range of fluid types and mixing duties, such as high intensity mixing and gentle product mixing. For low viscous products and basic applications like keeping the product homogenous, the mixer can handle volumes up to 40 m3.

How it works

The magnetic mixer transmits the required torque by means of magnetic coupling. The magnetic coupling consists of two sets of permanent magnets and a weld plate that separates the magnet sets. One set of magnets is mounted in the impeller (1) and the other set in the rotor (6). When the rotor revolves by means of the gear drive, the interaction between the two sets of magnets creates a magnetic coupling, which strenghting the rotation of the impeller. To avoid loss of magnetic coupling, it is necessary to gradually ramp up the rotation by means of a frequency inverter. The typical ramp up time is approximately 30 seconds. The frequency inverter is also used to adjust the speed.

Since the magnetic field couples across an air gap and through the weld plate(4), the tank is not compromised and therefore does not require a seal. This eliminates the risk of leakage and product contamination.

Alfa Laval Magnetic mixer - how it works

360° Service and maintenance videos

How to replace the female bearing and assemble

How to disassemble and replace the male bearing

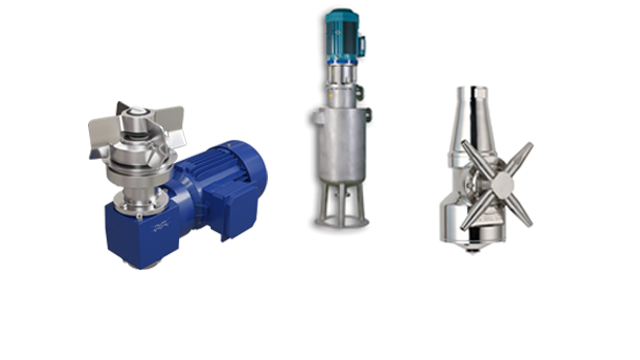

Part of a broad mixing range

Alfa Laval offers a comprehensive range of mixing equipment intended for hygienic applications in the dairy, food, beverage,home care, personal care, biotechnology and pharmaceuticals.

For a broader mixing range, explorer the differentproduct categories: Agitators and mixers.

You might also be interested in ...

ALB

Our bottom-mounted agitator ALB offers mixing solutions to meet any requirements in food, dairy, beverage, pharmaceutical, biotechnology and cosmetic applications.

Sani

Engineered for hygienic applications, Toftejorg Rotary spray head tank cleaning devices offer exceptional cleanability and drainability and easy, cost-effective maintenance.

Beam load cells

Ideal for mixing, dosing or batch tasks in small or mobile tank sizes up to 4000kg

Ten top tips - Tank Equipment

Here are some tips and service videos to show you how you can keep your tank equipment in tip top condition.

CAD portal

Download the product models in Neutral or Native CAD file formats. It is also possible to download 3D PDF files.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.

Tank equipment

near Newsletter

To keep you updated on important sustainability issues and opportunities in your industry and processes.