Level Switch

Level switches provide accurate and reliable remote liquid level indication for hygienic brewery, food and beverage, and biopharm processes.

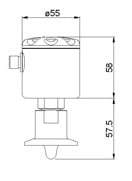

Compact, hygienic design

Alfa Laval Level switches are hygienic measuring devices that are especially suitable for detecting liquid levels in small process tanks used in brewery, food and beverage and personal care industries. This includes low-viscosity liquids, such as water and beer, as well as high-viscosity liquids and pastes, such as honey, yoghurt and toothpaste.

All wetted parts are made of AISI 316L stainless steel and PEEK, and designed to withstand process temperatures between -20 and +140°C. Because these 3-A certified level switches can withstand high temperatures, they are well suited for use in Cleaning-in-Place (CIP) and Sterilization-in-Place (SIP) processes.

Fast, accurate readings

Level switches enhance process reliability by delivering fast, accurate indication of the liquid levels. Integrated electronics provide a digital logic signal and incorporate automatic compensation for foam and bubbles as well as viscous, sticky media.

For more information, please refer to Documentation.

Product Benefits

- Compact, hygienic design

- Fast, accurate readings

- Provide a digital logic signal

Product catalogue

How it works

Operating principle

To measure the liquid level, the level switch employs a high frequency sweep signal, which is emitted from the sensor tip into the tank.

The media act as a virtual capacitor that, together with a coil in the sensor head, forms a circuit creating the switch point signal. This virtual capacity depends upon the dielectric value of the media, which is well defined for most media.