The technical teams for Alfa Laval ballast water treatment systems and Framo pumping systems have developed a solution for providing additional pumping head when PureBallast 3 Ex is installed in a deckhouse. By ensuring that the PureBallast 3 Ex system can handle its own pressure requirements, the optional booster pump unit (BPU) removes the need for changes in the existing ballast pumping system, thereby retaining its optimization and the vessel’s cargo offloading rates.

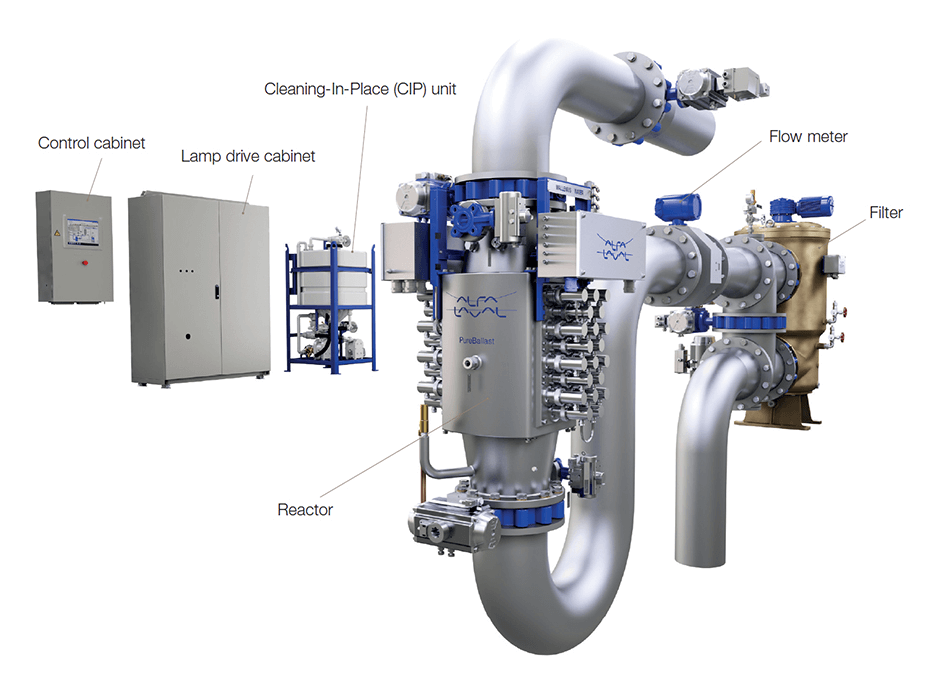

PureBallast 3 combines initial filtration with enhanced UV treatment in a specially designed reactor. PureBallast 3 Compact Flex, shown here, is the ideal system for most vessels due to its minimal footprint and high installation flexibility.

PureBallast 3 combines initial filtration with enhanced UV treatment in a specially designed reactor.

The main treatment process, occurs within an enhanced UV reactor. The reactor has a flow-optimized interior that ensures high turbulence and the concentration of the UV dose.

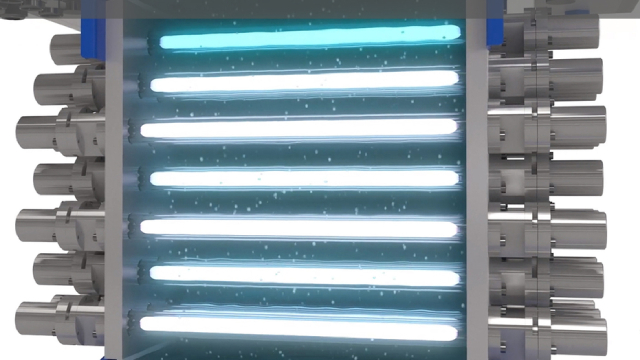

The medium-pressure UV lamps within the reactor employ specially designed lamp sleeves of synthetic quartz. These unique sleeves support transmission of a broader wavelength spectrum and provide more UV light during disinfection. Combined with the reactor’s internal design, this ensures optimal UV dosage and low energy consumption.

Supporting the reactor is a filter stage, used to remove any larger organisms and particles prior to biological disinfection. This improves the quality of water for treatment, especially when operating in cloudy coastal waters and fresh water.

In combination with the reactor, the effective basket filter design enables full-flow treatment of fresh, brackish and marine water with UV transmittance as low as 42%.

Alfa Laval PureBallast 3 uses an enhanced form of UV treatment, developed in cooperation with Wallenius Water. It performs without the addition of salt or chemicals, even when operating in fresh water.

Biological disinfection, which is the main treatment process, occurs within an enhanced UV reactor. The reactor has a flow-optimized interior that ensures high turbulence and the concentration of the UV dose.

The medium-pressure UV lamps within the reactor employ specially designed lamp sleeves of synthetic quartz. These unique sleeves support transmission of a broader wavelength spectrum and provide more UV light during disinfection. Combined with the reactor’s internal design, this ensures optimal UV dosage and low energy consumption.

Supporting the reactor is a filter stage, used to remove any larger organisms and particles prior to biological disinfection. This improves the quality of water for treatment, especially when operating in cloudy coastal waters and fresh water.

In combination with the reactor, the effective basket filter design enables full-flow treatment of fresh, brackish and marine water with UV transmittance as low as 42%.

The fully automated system ballasting process, when starting, it undergoes a brief start-up sequence. When ballasting begins, the incoming ballast water first passes through the filter stage. This removes any larger organisms and particles, which improves the quality of the water for treatment. The filter stage is of benefit for operation in cloudy coastal waters and fresh water. After filtration the water continues through the reactor stage, where it is disinfected by means of enhanced UV before entering the ballast water tanks.

Once ballasting is complete, reactor cleaning is performed via an automatic Cleaning-In-Place (CIP) cycle. This cycle is prompted immediately after ballasting and should be performed within 30 hours. The reactor stage is rinsed with fresh water when the CIP cycle begins and filled with fresh water upon its completion. The filter stage is also filled with fresh water once ballasting is completed. The same start-up and shutdown sequence, including CIP, is employed during both ballasting and deballasting.

The deballasting process is the same as the ballasting process. However, the filter stage is bypassed during deballasting since the water has already been filtered. After leaving the ballast water tanks, the outgoing ballast water passes through the reactor stage to eliminate any regrowth of microorganisms that may have occurred in transit. Having thus been disinfected to the established limits, it is discharged into the receiving water at the deballasting site.

UV ballast water treatment systems are chemical-free and pose no risk to the ballast water tanks. In PureBallast 3, cleaning is done through gentle, automated Cleaning-In-Place (CIP)

PureBallast 3 Compact Flex is the answer to space and flexibility concerns. Ideal for most vessels, it arrives as loose components for complete installation freedom.

Available for flows of 32–1000 m3/h, PureBallast 3 Compact Flex is delivered as loose components for easy, space-saving installation. With a compact design and the highest possible flexibility, it provides the answer to installation challenges – especially in retrofits and other situations where space is vital.

The treatment stages are integrated into the ballast water piping as inline components. Simple plug-and-play contacts reduce time and cost for engineering and installation, making PureBallast 3 Compact Flex the perfect fit for most projects.

A broad range of auxiliary equipment is available to support integration into any vessel, including backflush pumps, sampling points, valve packages and remote-control panels.

PureBallast 3 Compact Flex is available with both IMO and U.S. Coast Guard (USCG) type approvals.

PureBallast 3 Compact is a convenient solution for smaller ballast water flows. It integrates the system into a plug-and-play module with a small footprint.

Alfa Laval PureBallast 3 Compact can be delivered as a skid-mounted module, this makes it not only compact, but also easy to install due to minimized pipework. The skid has a minimal footprint and is connected via simple plug-and-play contacts. For flows of 32-300 m3/H.

All components are incorporated into the skid, apart from an electrical cabinet that is flexibly placed. This cabinet is a combination of the lamp drive cabinet and control cabinet of larger systems.

The following components are incorporated into the PureBallast 3 Compact skid-mounted:

A broad range of auxiliary equipment is available to support integration into any vessel, including backflush pumps, sampling points, valve packages and remote control panels.

PureBallast 3 Std systems handle large ballast water flows effectively, with a 1500 m3/h reactor size enabling streamlined and cost-effective system configurations. For potentially explosive environments they can be configured as PureBallast 3 Ex systems, which are available with deckhouse options for tankers.

PureBallast 3 Std systems can be configured for large flows and have the broadest installation parameters, including free placement of lamp drive cabinets within a 150 m radius. Individual systems can handle flows of 250–3000 m3/h, with dual systems providing coverage for up to 6000 m3/h. Because the 1500 m3/h reactor size means only one or two reactors are needed, the cost and complexity of large-flow systems are kept to a minimum.

The additional components are support systems that can be flexibly placed for an optimal design.

The same treatment and support components are used in PureBallast 3 Ex systems (see below).

A broad range of auxiliary equipment is available to support integration into any vessel, including backflush pumps, sampling points, valve packages and remote control panels.

PureBallast 3 for large flows and Ex-design, configurations available for 250-3000 m3/h, and even larger flows with multiple systems.

PureBallast 3 Ex systems are available for flows of 250–3000 m3/h, with dual systems providing coverage for up to 6000 m3/h. They can be supplied in range of Ex configurations according to ATEX and IECEx, Zone 1, IIC and T4. Design is simplified by the flexible placement of the lamp drive cabinets, which can be located outside the hazardous zone and up to 150 m away from the reactors they serve.

Redundant safety features, such as the connection of the reactor temperature and level sensors via relays that bypass the PLC, increase safety in operation.

Many tankers use submersible pumps to eliminate the need for a pump room and maximize space for product. This often leaves insufficient internal space for a ballast water treatment system. For this reason, pre-assembled PureBallast 3 Ex systems can be delivered in a standardize deckhouse, complete with all interior piping.

The flow-related components of the PureBallast 3 Ex system (UV reactor, filter and CIP unit) are contained within the deckhouse, while the lamp drive cabinet and control cabinet are installed outside the deckhouse and within the vessel’s safe zone.

PureBallast 3 Std and Ex systems are available with both IMO and U.S. Coast Guard (USCG) type approvals.

PureBallast 3 performs in the background, running in IMO-regulated waters at just 50% of its potential operating power in most situations. It can be ramped up to full power for the most difficult operating scenarios.

PureBallast 3 is a fully automated system. When initiated, it undergoes a brief start-up sequence.

When ballasting begins, the incoming ballast water first passes through the filter stage. This removes any larger organisms and particles, which improves the quality of the water for treatment. The filter stage is of benefit for operation in cloudy coastal waters and fresh water.

After filtration the water continues through the reactor stage, where it is disinfected by means of enhanced UV before entering the ballast water tanks.

Once ballasting is complete, reactor cleaning is performed via an automatic Cleaning-In-Place (CIP) cycle. This cycle is prompted immediately after ballasting and should be performed within 30 hours. The reactor stage is rinsed with fresh water when the CIP cycle begins and filled with fresh water upon its completion.

The filter stage is also filled with fresh water once ballasting is completed.

The deballasting process is essentially the same as the ballasting process. However, the filter stage is bypassed during deballasting since the water has already been filtered.

After leaving the ballast water tanks, the outgoing ballast water passes through the reactor stage to eliminate any regrowth of microorganisms that may have occurred in transit. Having thus been disinfected to the established limits, it is discharged into the receiving water at the deballasting site.

The same start-up and shutdown sequence, including CIP, is employed during both ballasting and deballasting.

UV ballast water treatment systems are chemical-free and pose no risk to the ballast water tanks. However, they depend on regular cleaning to remove seawater scaling and fouling from the UV lamp sleeves and sensors. Such build-up blocks the transmission of UV light, which can result in increased power consumption or faulty sensor readings that lead to system shutdown or non-compliant operation.

In PureBallast 3, cleaning is done through gentle, automated Cleaning-In-Place (CIP). CIP is preferable to both manual cleaning and automated mechanical wipers, which increase operating costs and risk performance-degrading damage to the lamp sleeves. Unlike other methods, CIP also cleans the UV reactor in its entirety.

The PureBallast 3 CIP system pumps a safe, biodegradable cleaning fluid into the reactor after each ballast cycle. Since there are no chemicals or moving parts, there is no risk to the environment, the lamp sleeves or the rest of the ballast water treatment system. Both PureBallast 3 and its market-leading performance are protected.

For ballast water flows of 85–300 m3/h PureBallast 3 Compact is a convenient, skid-mounted solution for smaller ballast water flows. Installation is easy due to the small footprint and minimized pipework.

-Skid-mounted, plug-and-play module

-Flexibly placed electrical cabinet

For ballast water flows of 85–1000 m3/h PureBallast 3 Compact Flex is the ideal choice for most vessels. Delivered as loose components, it maximizes space savings and installation flexibility.

-Complete installation freedom

-Minimized system footprint

For ballast water flows of 250–3000 m3/h PureBallast 3 Std provides the widest range of reactor configurations and technical opportunities on vessels with non-hazardous environments.

-Maximum range of operation and component placement

-Up to 6000 m3/h with dual systems

For ballast water flows of 250–3000 m3/h PureBallast 3 Ex gives vessels with explosive environments redundant safety features and high flexibility. The power supply can be placed outside the hazardous zone.

-ATEX and IECEx, Zone 1, IIC and T4

-Up to 6000 m3/h with dual systems

The images below may be downloaded for non-commercial use in discussing or presenting PureBallast 3. Reference to Alfa Laval must be made.

PureBallast 3 Ex systems are available for flows of 250–3000 m3/h, with dual systems providing coverage for up to 6000 m3/h. They can be supplied in range of Ex configurations according to ATEX and IECEx, Zone 1, IIC and T4. Design is simplified by the flexible placement of the lamp drive cabinets, which can be located outside the hazardous zone and up to 150 m away from the reactors they serve.

Redundant safety features, such as the connection of the reactor temperature and level sensors via relays that bypass the PLC, increase safety in operation.

The technical teams for Alfa Laval ballast water treatment systems and Framo pumping systems have developed a solution for providing additional pumping head when PureBallast 3 Ex is installed in a deckhouse. By ensuring that the PureBallast 3 Ex system can handle its own pressure requirements, the optional booster pump unit (BPU) removes the need for changes in the existing ballast pumping system, thereby retaining its optimization and the vessel’s cargo offloading rates

If your vessel is a tanker, ATEX requirements might not be your only issue. If you use submersible cargo pumps, you probably don’t have a pump room or much other space for a ballast water treatment system. Fortunately, Alfa Laval can provide a deckhouse, so that you can install topside. More than just a container, a deckhouse is a protective, insulated solution – with an integrated booster pump option, to help out if your existing ballast water pumps aren’t strong enough.

If your vessel is a bulker, you probably load cargo at twice the rate you unload it. If so, you deballast at twice the speed of ballasting. That gives you an opportunity to save. A PureBallast 3 bulker-fit configuration adjusts the UV reactor and filter capacities, so that you install only what a bulker needs for compliance. Not only does it create a smaller system footprint, it also lowers your investment and operating costs.

PureBallast 3 documentation for shipyards and other installing parties is divided into:

Direct assistance from Alfa Laval is also available to aid design and planning, as well as in the installation and commissioning processes.

Download Alfa Laval’s ballast water management resources to learn more about PureBallast 3 and how it compares to other available treatment technologies. To obtain design and installation documentation or more information, please contact Alfa Laval.