Foodec Hygiene Plus - advanced food processing

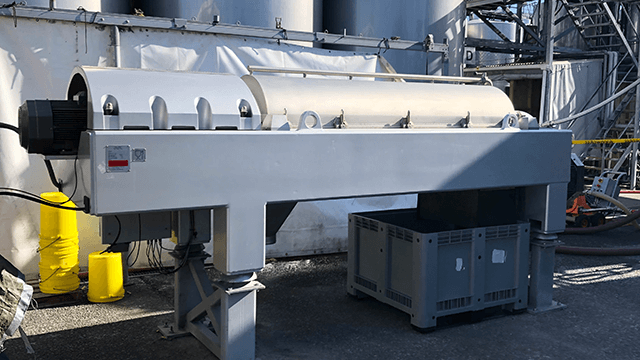

The food industry’s requirements for hygiene are always developing, so Alfa Laval continuously improves its decanter solutions to include hygienic features and designs which set new standards. Using advanced food processing technologies, the Alfa Laval Foodec Hygiene Plus is engineered to deliver optimal uptime thanks to its outstanding reliability. Foodec Hygiene Plus is a food decanter designed to better meet the needs of an evolving food industry.

Centrifugation in the food industry - extra features designed to boost hygiene levels

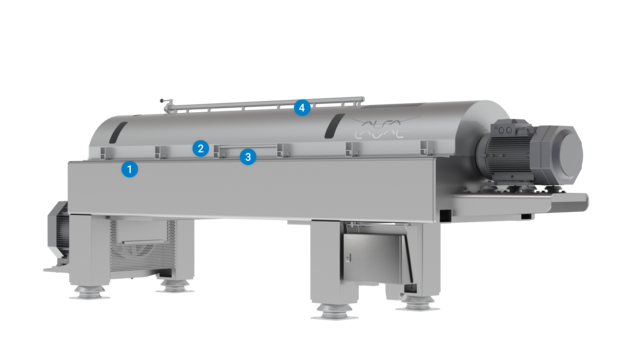

- The drainage hole ensures that minimal residue is left in the food decanter centrifuge after operation, making cleaning more efficient.

- The product wetted surfaces inside the Foodec Hygiene Plus are designed and engineered to be as smooth as possible, making cleaning easier and more effective. The smooth surface also reduces the build-up of biofilm.

- CIP feed tube, critical dead-end areas of the feed tube are now easier to clean. In particular, the area around the decanter feed zone and the tapered cone section can also be cleaned much more effectively.

- The integrated cleaning-in-place bar is a new, optimized design which makes it easier to clean every part of the inside of the frame and the outside of the bowl while minimizing the amount of cleaning media required.

Alfa Laval Foodec decanter centrifuges are best-in-class when it comes to performance and efficiency. With the Foodec Hygiene Plus, extra features designed to boost hygiene levels are included as standard. These features can also be installed to existing decanters as an upgrade, bringing older solutions up to existing hygiene demands and expectations. Where hygiene is even more important, we can also offer additional features to further boost cleanliness.

TrueStainless™

Designed for long-lasting and unmatched hygiene.

TrueStainlessTM ensures solid stainless steel is used for the frame and other key parts that may be in contact with corrosive atmospheres, leading to optimal hygiene and longer equipment life.

SaniRibs®

The cleaner, more efficient way to transport solids.

Our unique seal welded ribs create optimal friction which offers better, more efficient solids transportation. This innovative technology also eliminates pathogen hot spots and allows for easy cleaning, meaning longer production runs, less manual maintenance, and improved profits.

Documents

Why is food safety getting even more important in the food industry?

Food safety and hygiene in food processing is becoming increasingly important, setting higher demands on the food processing equipment and centrifugation in the food industry.

- What is considered as sufficient hygiene has changed dramatically over the years, as awareness around food safety has increased and more advanced data and research allows us to see contaminants and dangers that were perhaps not visible before.

- Maintaining hygiene in food processing equipment is essential when it comes to ensuring a perfect final product with exactly the right taste and texture.

- Maintaining the right hygiene levels can also improve overall productivity, while more efficient cleaning processes help minimize unscheduled downtime.

Evolving demand is what constantly drives us to engineer solutions using advanced food processing technologies. Solutions which exceed our customers’ expectations of hygiene and performance in a decanter centrifuge. That is why we have developed Alfa Laval Foodec Hygiene Plus – a state-of-the-art solution for the food industry.

Services

Effective maintenance of Foodec Hygiene Plus food decanters is essential for ensuring optimal process performance alongside the best possible hygiene levels.

Depending on process conditions such as running time, type of raw material, process temperature and the number of CIP cycles, Alfa Laval recommends having a decanter inspection at least every 4-6 months, and a major service at least once per year. Qualified Alfa Laval field service engineers can perform service and inspection either on site or in an Alfa Laval service center, so you can decide which works best for your specific needs.

Maintaining the condition of your bowl and conveyor is a crucial part of decanter maintenance, and it is the key to securing consistent performance and optimal hygiene. Bowl and/or conveyor repair must be carried out at an Alfa Laval service center.

With connected services such as remote monitoring and online support, maintenance intervals can be extended. Maintenance, repairs, condition monitoring and remote access can be offered as a package in a single Service Agreement, tailored to your specific needs. Alfa Laval also offers training for on-site maintenance staff.

Contact our dedicated service expert for a Service Agreement offer that meets your specific requirements.

Happy customers

How New Zealand’s wine industry innovates for sustainable growth with decanter technology

"We chose Alfa Laval due to their service, proven track record and people with relevant process understanding, delivering the same performance as other decanter manufacturers with a smaller, better priced unit"