Corporate water stewardship

Water is quickly emerging as the most critical resource on the planet. Industrial production plants increasingly face obstacles with regards to the availability of freshwater and adequate wastewater treatment. These challenges are accelerating with the upturn in global warming and as production output keeps pace with rising consumer demand across various sectors. A rise in policy response to constraints on water resources and water contamination adds pressure as companies adapt to comply with new regulatory restrictions pertaining to water withdrawals and discharge.

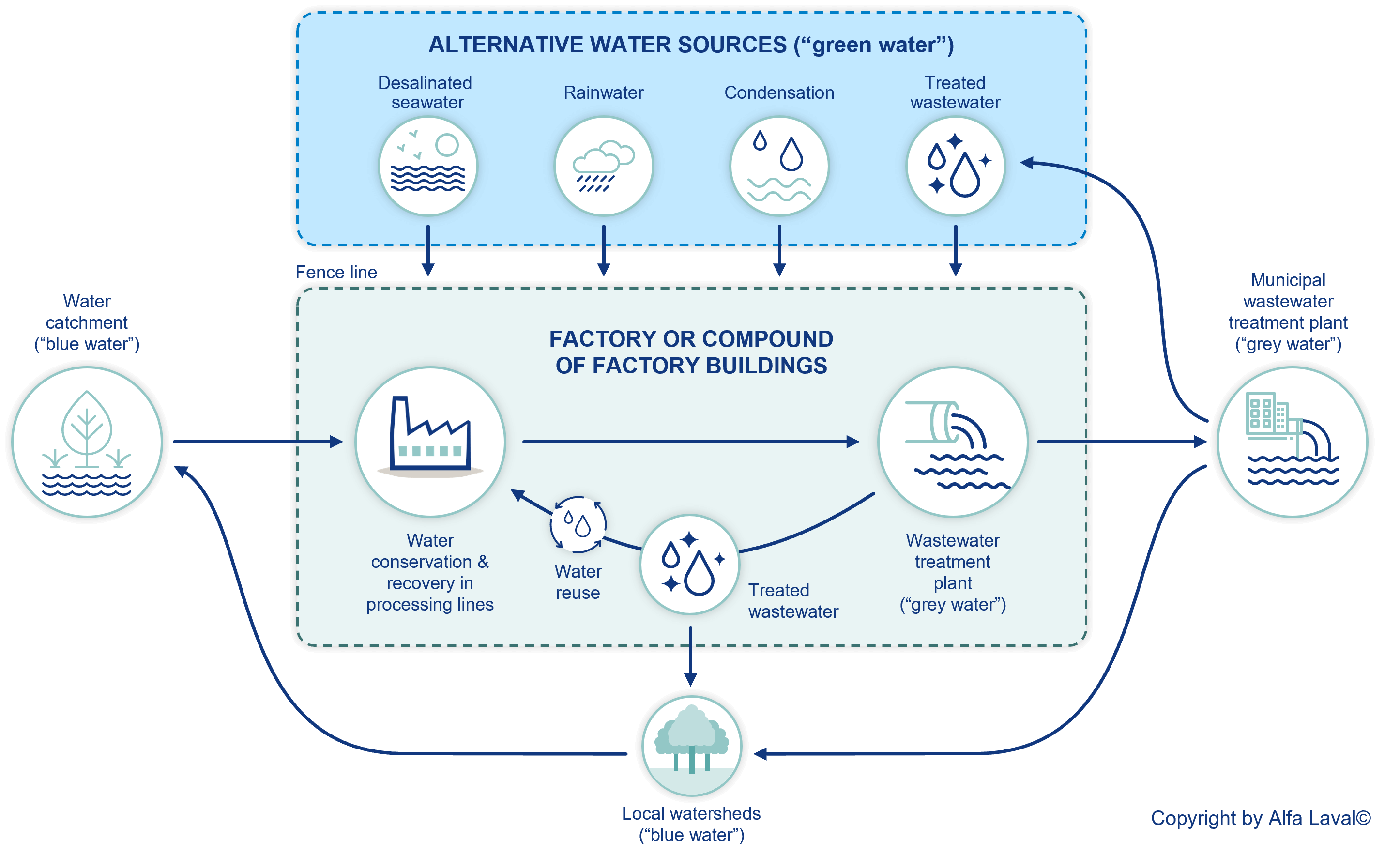

Alfa Laval enables corporate water stewardship for a wide range of industries. With solutions and competences accumulated over many decades and industries, Alfa Laval empowers industrial plants to optimize their water footprint by focusing on water conservation, wastewater treatment, water reuse and the establishment of circular water systems. In this way, plants can gradually progress towards achieving water neutrality as the gateway to future water-positive operations.

The complexities and local nature of corporate water stewardship are well-known to Alfa Laval’s many experts in this area. A local presence combined with global competence centres gives us the footing we need to engage and meet companies to advise on the choice and implementation of the right solutions with the optimal effect, durability, and total cost of ownership.

Towards water neutrality and water-positive operations

Many companies have assessed or are currently assessing their water footprint – either prompted by necessary risk management due to dwindling water resources or driven by stricter regulations, which are forcing their hand.

Partnering with Alfa Laval makes it feasible for most industrial plants to achieve water-neutral operations and negate the water footprint. Industries and sectors reliant on water consumption must add water to the processing line, which can still be done in line with ambitions to minimize or negate the water footprint. Collecting rainwater or condensation water, reusing adequately treated wastewater, or desalinating seawater are all options to consider. Regardless of the chosen approach, Alfa Laval’s solutions enable companies to achieve water-neutral operations as an important milestone in their sustainable water management.

In some hotspots around the world, water stress is so severe, and watersheds so degraded by human influence that a company’s license to operate may be called into question. The company may either be refused a license to operate by local officials or forced to take measures to support and sustain a license. Establishing water-positive operations will strengthen a company’s license to operate as it contributes towards replenishing and restoring local watersheds, solidifying the company’s position.

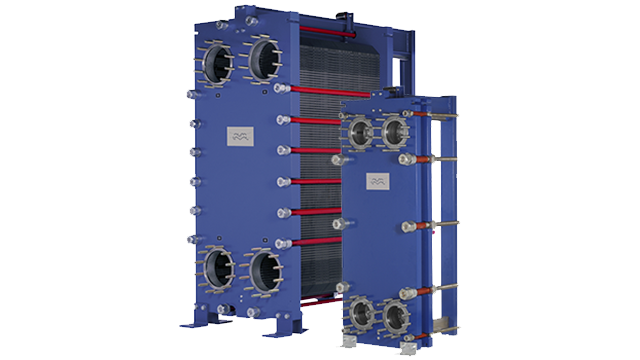

The optimization of circular water systems in processing lines is both a cornerstone in water stewardship and a strategic shift aimed at minimizing a plant’s dependency on water withdrawals. With Alfa Laval’s solutions, companies may significantly minimize water withdrawals and carbon emissions.

Across industries, Alfa Laval’s solutions can recover water for reuse to sustain a closed water loop of up to 98 percent of all water. In addition, companies may simultaneously recover valuable, dissolved, and suspended materials for reuse or to create a new revenue stream.

Hygienic processing lines in the food, beverage, and pharmaceutical industries will benefit from the continuous optimization of water for cleaning and cooling. Alfa Laval’s subject-matter experts advise on selecting solutions that meet both cleanliness and sustainability benchmarks. Digital monitoring and surveying tools enable data-driven optimized water circularity and superior energy efficiency with an attractive payback time on the investment.

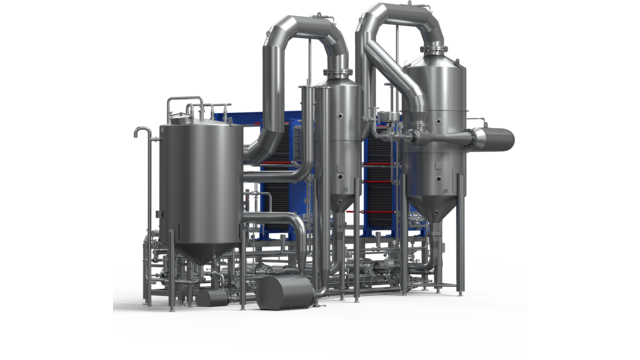

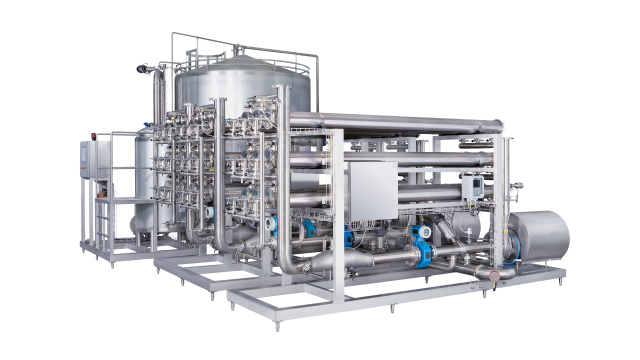

Industries where water is an ingredient in the end-product – such as beer, milk, beverages etc. – will benefit from exploring Alfa Laval’s evaporators and membrane systems. These solutions enable the extraction of water from the end-product ahead of transportation, while the extracted water – known as condensate – may be treated and reused to strengthen a circular water system in the processing line.

Water recovery and circular reuse

As plant-based drinks producers look to increase production in a global market predicted to rise to USD 71.46 billion by 2030 (Facts & Figures Research, 2023), innovative leaders in the industry are incorporating ‘sustainability as standard’ and building circularity into their expanding operations.

Fresh yeast with less water

Water will be a significant challenge for the food and beverage industry in the coming decade in terms of sustaining and growing production at current locations. For a leading global yeast producer, the requirement for five liters of water for every 50 grams of yeast produced is already a reality.

Steps to climate proof your brewery

To make beer, you need a lot of water. And you need good water. The availability and quality of the water will increasingly dictate where beer will be produced. These are all well-known facts.

Industrial wastewater and reuse

Wastewater as a source of “grey” water – i.e., water sources that may be converted into a “green” water source – is attracting the attention of both regulators and industries. Adequately treated wastewater can be better reused to enhance profitability and circularity within processing lines, while also safeguarding the more vulnerable and sensitive “blue” water sources – such as groundwater and surface waters. Today, only 2.4 percent of wastewater across the EU is reused (Global Water Intelligence, 2023).

Alfa Laval, with its array of solutions and extensive expertise in the fields of industrial and municipal wastewater treatment, offers a wide range of industries the opportunity to secure cost-competitive, efficient, and sustainable methods for treating and reusing their wastewater. Additionally, industries benefit from the recovery of valuable resources – such as heat and finite resources, including phosphorous and nitrogen.

Solving the palm oil mill effluent challenge

Palm oil production is on the increase, which brings with it major economic benefits, but also significant sustainability challenges in terms of the impacts it has on the environment with the generation of methane, water and land use, and waste management

Water recycling solution generates EUR 30,000 in cost savings

With the global population set to grow to 9.7 billion people by 2050 (UN, 2024), and ever-changing and growing consumer demands and economic climate shifts, a biosolutions giant headquartered in Scandinavia helps food and beverage producers around the world generate more from less.

In search of ways to tackle Mexico’s big water challenge

In May 2023, close to half of Mexico’s municipalities were in drought, according to the country’s National Water Commission. A year later, when the country went to elect a new president, much of the country was suffering from historic drought, water shortages, intense heat and occasional power outages.