Pyrolysis

To accelerate the net zero transition, we need technologies that enable and complement conventional recycling methods like mechanical recycling (PET).

Pyrolysis is the dominant recycling technology for the future. Recycling via pyrolysis converts low-value waste, such as plastic, tires and biowaste, into new materials.

Alfa Laval know how enables you to reach:

- Energy efficiency and fouling corrosion abatement

- High yield quality and plant operation uptime

- Efficient water and waste management

The pyrolysis process

The process involves thermally decomposing feeds in an oxygen-free environment. During pyrolysis, molecules break down, forming new molecules. The new molecules become pyrolytic oil. This pyrolysis oil can be used as a petrochemical feedstock for producing recycled plastics

Unique challenges of pyrolysis recycling

The pyrolysis process is particularly effective for waste plastics that may otherwise be difficult or impossible to recycle. By converting these plastics into valuable chemicals, it provides a viable solution for their reuse or disposal. Ultimately, pyrolysis lets us reduce the negative impact of plastic waste on our environment, while creating profitable opportunities for businesses. Although it has a promising future, pyrolysis is not without challenges, particularly with regards to the technology. The challenges are diverse and varied, with each one presenting unique difficulty:

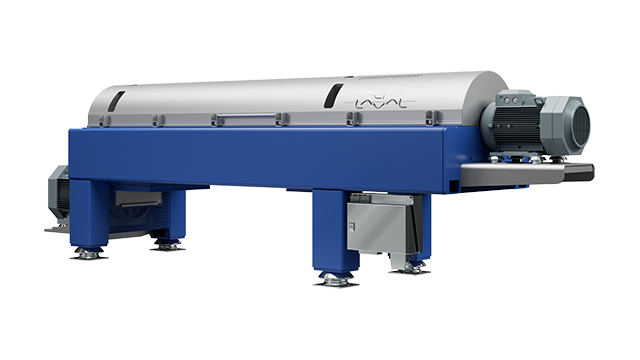

Key components

Pyrolysis output

Low carbon biofuel

Through pyrolysis, plastics, tyres and residual materials from wood production can be converted into an oil, which can then be refined into renewable low carbon biofuel.

Plastics

The pyrolysis process recovers oil from recycled plastics, which can be used as a chemical feedstock to create new plastic products.

Tires

Carbon black is recovered from recycled tires in the pyrolysis process. There are significant economic and environmental benefits since new tyres consist of 40% carbon black.